CMM (Coordinate Measuring Machine)

CMM (Coordinate Measuring Machine)

Product Lineup

The XM Series is a handheld coordinate measuring machine (CMM) that lets anyone easily measure 3D/GD&T features. The system is portable and shop-floor ready, so measurements can be taken in any location. The unit also automatically records measurement data and creates detailed inspection reports. The images showcases our latest XM-5000 model which allows high-accuracy measurement for palm-sized parts to large applications.

The WM Series Coordinate Measuring Machine is a new handheld CMM designed accurate 3D and GD&T measurements over a large 15m (49 ft) area. Similar to the XM Series, the unit is portable and shop-floor ready, so measurements can be taken in any location including in the machine tool. The unit also automatically records measurement data and creates detailed inspection reports. The image showcases our latest WM-3000 model which uses a wireless, handheld probe with on-screen visual guidance to have a single operator easily inspect parts with complex dimensions or would normally require multiple inspectors due to part size.

A coordinate measuring machine (CMM) is a measuring device that measures the geometry of objects by establishing discrete points on a physical surface using a contact probe. The machine will specify the probe's position in terms of displacement from an origin point in a three-dimensional coordinate system (XYZ axes). A CMM can measure critical 3D dimensions with high-accuracy, record the measured data and obtain complex GD&T features. Non-contact models use other methods such as cameras and lasers.

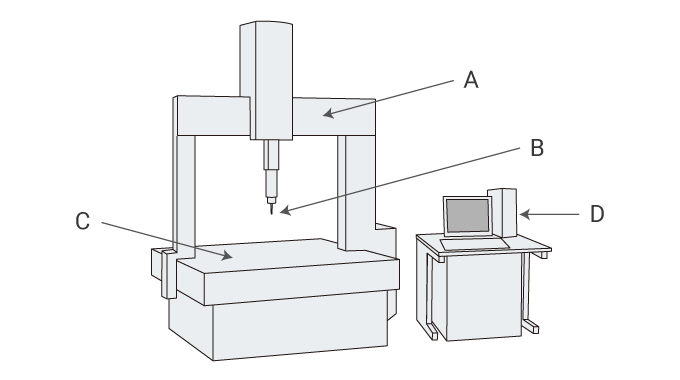

Coordinate Measuring Machine (CMM) Parts

A: Moving bridge, B: Trigger probe, C: Stage, D: Controller

Benefits of Coordinate Measuring Machines (CMMs)

Coordinate measuring machines (CMMs) have three-dimensional measurement capabilities (X, Y, and Z directions), unlike hand tools such as micrometers, vernier calipers, or height/depth gauges, which are limited to measurement in only one direction at a time.

CMMs accurately track a probe tip in 3D space and create dimensional measurements through shape building via the points taken through contact with the measurement piece. An even greater number of points can be taken over a larger area on the part to map the surface and compare to CAD data for shape, form, and warpage inspection.

A powerful advantage of coordinate measuring machines (CMMs) is that they can measure items that are difficult to measure with other measuring machines to a high degree of accuracy.

Another feature that stems from the CNC nature of the measurement system, is the ability to measure the three-dimensional coordinates of a specific point (a hole, etc.) from the virtual origin with a hand tool such as a caliper or micrometer. Also, measurement using virtual points and virtual lines and geometrical tolerances are difficult with other measuring machines but can be measured with a 3D CMM machine.

Coordinate measuring machines (CMMs) are automated inspection tools. Skilled programmers create a measurement routine or program by measuring any required 3D or GD&T dimensions on a part.

Once the program is registered and an origin point is established through a coordinate system, parts can then be fixtured in place and operators can have the coordinate measuring machine run an automated measurement procedure. While there is a good amount of time

Comments