3d printing and Robotics

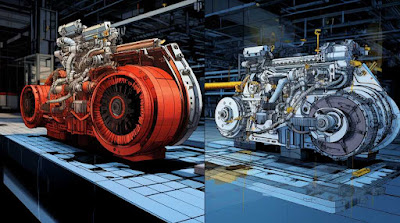

3D Printing 3D printing is a process of making three-dimensional objects from a digital file. This rapidly growing technology has revolutionised how mechanical engineers design and produce parts and components. 3D printing also allows for the creation of custom parts and components quickly and easily It can reduce the cost and time associated with traditional manufacturing processes. As technology advances, the cost of 3D printing will decrease, and the quality of the parts and components produced will increase. In the medical industry, 3D printing technology can be involved in creating the following, Custom prosthetics Bionic Hands Prosthetic upper limb Implants Medical devices In the automotive industry, 3D printing technology can produce parts and components for, Cars Trucks Electric vehicles Robotics Robotics is becoming increasingly important in mechanica...