Production process

Production process

The production process is an essential part of any business. It is a process of turning raw materials and ideas into products and services. It is important to develop efficient and effective production processes because they heavily impact business performance.

Definition

The production process is defined as the process in which the factors of production, i.e. inputs of resources, are turned into products or services.

Examples of the production process

Let's explore the production process with the example of biscuit production. To set up this production process, the company requires a place or land to set up the whole production unit.

Secondly, in the production of biscuits, the organization will need the machines to mix all the necessary ingredients. It will also need an oven to bake the biscuits. In addition, it will need machinery for making the biscuits' packaging and labelling, which will all become capital investment for the company.

The company will also need labour to mix all the ingredients together, separate them into batches of production and different flavours, set the output levels of the machines and temperature of the ovens, decide on the labeling function, and oversee the overall production system.

Another important function and need of the production process is technology to ensure the labels are correct, the names of the product are rightly mentioned, the temperature is set correctly, and all other necessary technical aspects that do not require human intervention.

If all of the above factors of production are in place, the production process of biscuits runs smoothly and can match the requirement of the business and customers.

Types of production

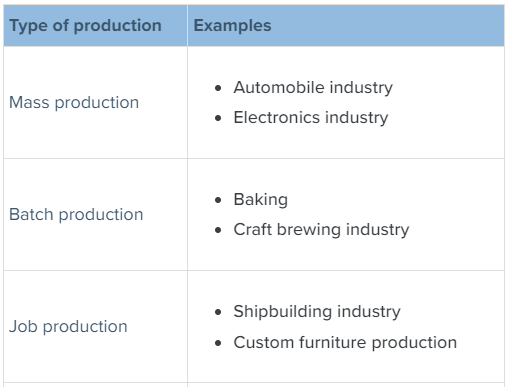

The methods of production can be classified into many types depending on the company’s product and the organization’s needs.

a) Mass production,

b) Batch production,

c) Job production,

a) Mass Production

Mass production means there is continuous production and all employees work continuously to produce the same items at the same time. In this kind of production, the forms and size of the products remain the same and every employee focuses on the same product. All resources are utilized to produce the same range. To make production more efficient and effective, multiple tasks may be carried out at once to get quick results.

Example:

If one company is producing only white bread on a huge level, all employees will focus on the white bread packets only. In this process, most employees will be working towards white bread making: preparing the dough, baking, etc. Others will be working on packing the produced loaves of white bread at the same time, to generate the loaves of white bread quickly and efficiently at once.

b) Batch Production

Batch production is similar to mass production. However, the products may be produced in batches. This means that the production may be divided based on product size, colour, form, etc.

Example:

We can understand this with the example of T-shirt production. The T-shirt manufacturing company may opt for batch manufacturing, as they would want to manufacture in different sizes from small, medium and large, and also in different colours, say red, blue, green, and yellow. Hence, the team may be divided for every batch on the basis of production of the respective size and colour.

c) Job Production

Job production means the products are produced in a limited quantity and may be specific to customer preferences. Job production is small-scale, and the task of producing an item or product is completed before taking up other jobs.

Comments