engine components

Different Parts of the Engine and their Function:

- Cylinder Block

- Cylinder Head

- Piston

- Piston Rings

- Connecting Rod

- Crank

- Crankshaft

- Combustion Chamber

- Manifold

- Intake Manifold

- Exhaust Manifold

- Intake and Exhaust Valves

- Gudgeon Pin or Piston pin

- Spark Plug

- Fuel Atomizer or Injector

- Poppet Valves

- Carburetor

- Flywheel

- Engine Bearing

- Governor

- Push Rod

- Rocker Arm

- Catalyst Converter

- Supercharger

- Turbo Charger

- Radiator

- Fan

- Timing Belt

- Fuel Tank

- Sensor

- Water Pump

1. Cylinder Block:

Cylinder Block is the main part of the IC (Internal Combustion) engine. It is the part where all the functions of the engine take place inside it, such as intake, Suction, Compression, Combustion, Exhaust, etc.

The function of the cylinder in IC engines is to hold the fuel and guide the piston.

The cylinders are made of Cast iron and Cast steel by the process of casting to handle all the temperature and pressure which is generated after the combustion of fuel.

So the cylinder is designed in such a way that its compressive strength is high. It also requires cooling in the engine cylinder because of high pressure and temperature.

#2. Cylinder Head:

The cylinder head is the top cover of the engine cylinder which covers the cylinder from the topside to seal the cylinder and does not give a permit to air and gas to enter and exit from the system.

The head is made as per design requirements by cast iron or aluminum by the manufacturing process of forging or casting.

The cylinder head consists above the cylinder block and contains various components such as a spark plug in a petrol engine, inlet valve, exhaust valve, and injector for fuel supply in case of a diesel engine.

For proper leakproof between cylinder and cylinder head, an asbestos packing and metal gasket are provided.

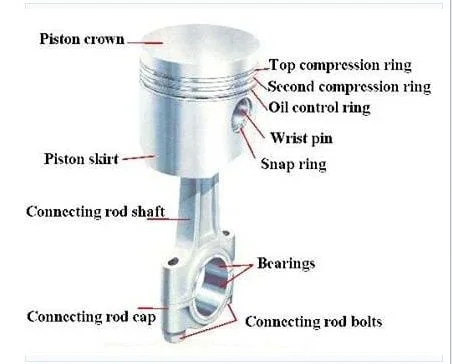

#3. Piston:

A Piston slides inside the cylinder in reciprocating motion and transfers mechanical energy to the crankshaft with the help of connecting rod.

The piston is designed in such a way that it is strong, light, and sufficient to handle the pressure and temperature which is generated after the combustion of fuel.

The piston is made up of cast iron or sometimes made of aluminum alloy.

4. Piston Rings:

The piston rings are used to provide the sealing effect between the cylinder and the piston. It helps to do not leak the engine’s combustion gas and bypass the piston and also helps to overcome the friction around the piston.

Piston rings are made up of cast iron and alloy cast iron. It is of two types:

- Compressor Ring (Pressure Ring)

- Oil Controller Ring

Compressor Ring transfers heat from the piston to the cylinder liner and it is inserted into the top grooves of the piston. Compressor rings are also used to overcome the side thrust over the piston which causes fluctuations.

The oil controller ring maintains the proper lubrication between the cylinder and the piston and is placed under the pressure ring. it also maintains access to lubrication.

#5. Connecting Rod:

A connecting rod is used to connect the piston to the crankshaft with the help of a piston pin and crank pin.

Connecting rod transmits the reciprocating motion of the piston to into rotary motion of the crankshaft so this is works as a lever arm that transfers the motion from one end to another end.

One end is called the big end which is connected to the crankshaft and another end is called the small end which is connected to the piston.

Connecting rod made up of Low carbon steel, for the small engine, it is made up of cast aluminum alloy by the manufacturing process of Heat treatment and forging process.

#6. Crank:

Crank means simply rotating or turning the engine’s crankshaft. The crank works as a rotating member that receives power from the connecting rod and transmits to the crankshaft, so the crank works as a lever between the connecting and crankshaft.

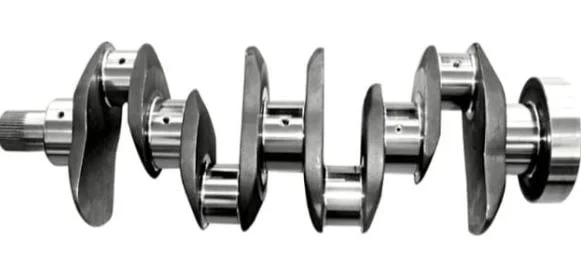

#7. Crankshaft:

In an engine, the crankshaft receives the power or efforts or thrust by the piston through the connecting rod and transmits this power of reciprocating motion of the piston into rotary motion of the crankshaft which is further connected to the flywheel and transmission shaft which is used to move the vehicle.

Crankshaft made by casting and forging process using the material of alloy steel or cast iron.

#8. Combustion Chamber:

The combustion chamber is enclosed with a cylinder head, cylinder walls, piston head where the combustion of fuel has occurred.

Aluminum is used as a material in the combustion chamber because it dissipates heat higher than cast iron.

In the combustion chamber, four-round holes are used for valves to reside.

#9. Manifold:

There are two manifolds in the engine Intake and Exhaust Manifold.

Intake manifold: The intake manifold is connected to inlet valves, It is the pipe that helps to provide air-fuel mixture into the engine for proper combustion.

Whereas in diesel engine intake manifold is used for bringing only air to the combustion chamber.

Exhaust Manifold: Exhaust manifold is responsible for taking out the exhaust gases from the combustion chamber after combustion which is further connected to the exhaust valves and its design and construction are the same as the inlet manifold.

#10. Intake and Exhaust valves:

Intake and Exhaust valves both are responsible for regulating and controlling the charge of air and fuel mixture for coming and burning in the combustion chamber and thereafter to go out the charge of the air from the engine cylinder.

Both valves are situated either on the cylinder head or on cylinder walls in various shapes generally mushroom shapes existed.

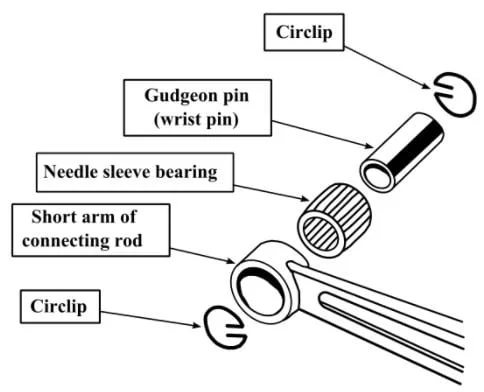

#11. Gudgeon Pin or Piston pin:

Gudgeon pins connect the piston to the connecting rod at the small end. It is also called a Piston pin, a piston pin made hollow for lightweight.

#12. Spark Plug:

The spark plug is a device that is used to generate the spark between the two electrodes and ignited the combustible mixture within the combustion chamber. It should be able to withstand fluctuating pressure and temperature.

So its main function is to conduct the high potential from the ignition system into the combustion chamber.

The spark plug provides the proper gap across which spark is produced by applying high voltage to ignite the fuel in the CC.

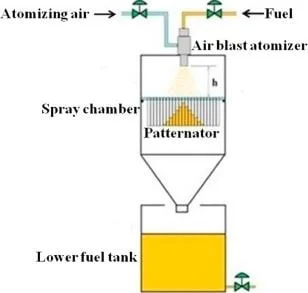

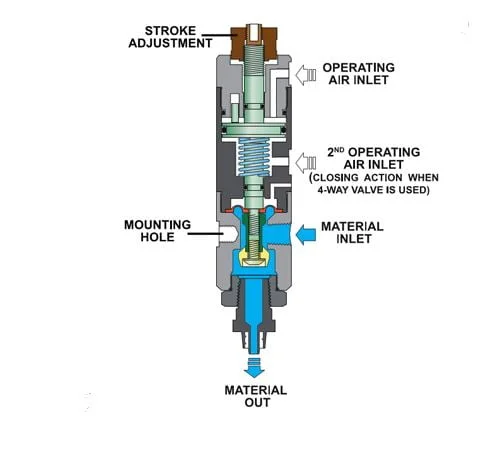

#13. Fuel Atomizer or Injector:

Here Fuel is injected by means of an injector at the end of the compression stroke and proper atomize of fuel into fine droplets.

In a Diesel engine or CI engine, Air is alone drawn into the cylinder during suction stroke and compressed to very high pressure.

Due to compression, the temperature and pressure of air are raised to a value required for ignition of the fuel, so during the injection process, fuel is broken into a fine spray of a very small droplet.

These droplets take heat from the hot compressed air so these droplets of fuel change into the vapor and get mixed with air.

Due to continuous heat transfer from the hot air to the fuel, the temperature of fuel reaches a value greater than the self-ignition temperature of fuel and fuel starts to ignite.

#14. Poppet Valves:

The poppet valve is a fast-acting, and high-flow valve. It is connected with pressure control types of equipment and applications for directional control flow.

Poppet valves are made up of valve stem and metal flat disks. This valve has a mushroom-shaped head which is used in an engine by opening and closing the intake and exhaust ports in the cylinder head.

#15. Carburetor:

The process of preparing a combustible fuel-air mixture outside the Spark Ignition engine cylinder is called Carburation.

A carburetor is a device that atomizes the fuel and mixes it with air. A carburetor is used in a petrol engine, it is a mixing device to supply the engine with an air-fuel mixture.

It atomizes the fuel and mixes it with air in varying proportions to meet the condition of automotive engines. It is also used to reserve the quantity of fuel supply and maintain fuel at a constant head.

The carburetor is connected with the intake manifold of the engine.

#16. Flywheel:

Flywheel means fluctuation of energy, it reserves the energy and uses this energy when requires it. A Flywheel is an inertial (force) energy storage device.

The flywheel absorbs mechanical energy and serves as a reservoir during the period when the supply of energy is more than the requirement and releases it during the period when energy is less than required.

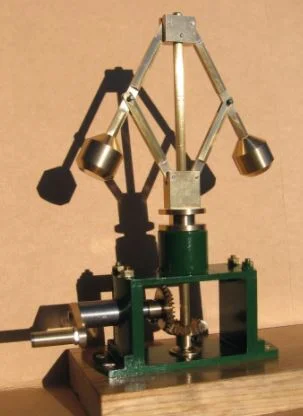

#17. Governor (Automobile):

Governor controls the variations of load and maintains the speed of the engine within a specific unit. it controls the speed of the engine by regulating the supply of fuel.

In governor, there are metal valves that rotate about an axis and generate centrifugal force.

Governor is a self-acting device. it controls the speed of the engine. when the load on the engine suddenly increases the engine speed will be decreased greater decrement in engine speed can stop the engine.

It is connected to the engine crankshaft when the speed of the engine decreases, the governor also slows down and the sleeve moves downward that opening the valve of fuel supply with the help of lever increment in fuel increase the speed of the engine to mean speed.

Whereas, in the second case when the load on the engine decreases, Governor also decreases the fuel and controls the speed.

#18. Engine Bearing:

The bearing is a machine part that gives a free rotation of the shaft with minimum friction.

It supports other moving elements and permits a relative motion between the contact surfaces of the members and elements while carrying the load.

Several Bearing is used in the engine in which a bearing that allows the crankshaft to rotate is named engine bearing.

It is a device that is used to reduce the friction between moving parts of machine elements to provide movement in a desired with minimum power losses.

The function of Bearing:

Here I have listed three functions of Bearing:

- Reducing friction

- Supporting parts of the machine or machine elements

- Bearing radial or thrust loads

#19. Catalyst Converter:

Catalytic converters help to change the harmful gas from engine emissions into safe gases, like steam.

It is situated on the underside of the auto vehicle where two pipes come out of it, converter utilizes two pipes and the catalyst during the process of making the gases safe to be expelled.

The catalytic converter is an exhaust emission control device that is using chemical reactions and redox reactions, it reduces toxic pollutants and gases from exhaust gases in an ic engine.

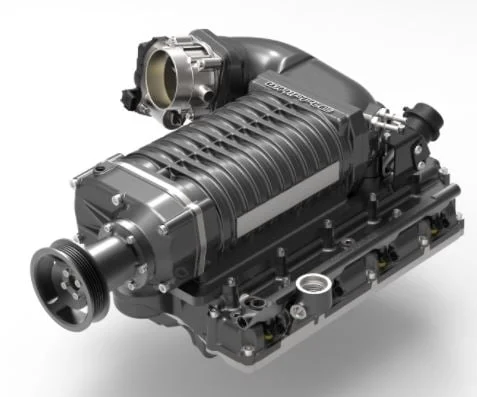

#20. Supercharger:

It is the method of supplying air at an increased density to the engine so that more amount of fuel can be burned in the same cylinder space.

So supercharging is achieved by raising the pressure of the inlet by means of a pressure boosting device called a Supercharger.

Objectives of supercharging:

The main objectives of Supercharging are:

- To obtain more power from an existing engine

- Supercharging is used to maintain power output

- To get more power output for a given weight of the engine.

Advantages of supercharging:

The following advantages of Supercharging:

- It increases the power output

- Greater induction of charge mass

- Better atomization of fuel

- Better mixing of fuel and air

- More complete and smoother combustion

- Reduces exhaust smoke and

- Increase overall efficiency.

#21. Turbocharger:

In this method, the supercharger is driven by a gas turbine which uses the energy of exhaust gases. The turbine is connected to the compressor by a turboshaft.

The air sucked by the turbine into the compressor is thrown outward by centrifugal force.

#22. Radiator :

The radiator is used in engine cooling systems for heat transfer where it helps to transfer thermal energy from one medium to another medium for cooling and heating purpose.

A radiator is a heat exchanger which eliminates excess heat from the system.

#23. Fuel tank :

A fuel tank is situated under the middle or rear of a vehicle or car. The fuel tank is responsible to store the fuel for vehicles.

Fuel tanks come in a variety of sizes and dimensions, it depends on what the capacity of fuel is for a particular vehicle and where it requires to be set in the vehicle. it is also called a gas tank or petrol tank.

#24. Timing Chain or Belt:

Timing belts or chain is used to connect the crankshaft to the camshaft in an internal combustion engine, which helps control the closing and opening of the engine’s valves.

It helps to perform in vehicle’s engine to operate smoothly. It connects the engine’s crankshaft to the camshaft and plays a crucial role in controlling the valves and pistons in our automobile vehicles.

In design, the timing belt is made up of a reinforced rubber band with high tensile fibers with notches or teeth on the inner side that helps very precisely synchronize the opening and closing of the engine’s valves.

In an Internal combustion engine when the crankshaft turns, the crankshaft sets the timing belt in motion.

Then timing belt turns the camshaft and helps to closes or open each valve and it gave permission to the pistons to move up and down.

So overall we can say that the Timing belt control all of the opening and closing of the valves and in each phase also control the timing of the pistons throughout all phase.

The timing belt allows each and every step to complete in a very precise order.

#25. Push rod:

The pushrod is the part of an internal combustion engine that helps to connect and transfer motion from the camshaft to the valves.

Pushrod connects from the camshaft and rocker arm to convert the rotary motion of the camshaft into the pulse motion of the rocker arm.

In design, Pushrods are slender metal rods and long in dimensions of the size which is situated on the top head valve and then goes up into the rocker arm.

Whereas, the bottom end of a pushrod is fitted with a lifter, where the camshaft makes contact.

After that, the camshaft lobe moves the lifter upwards, which moves the pushrod, and on the other hand, the top end of the lifter pushes on the rocker arm, which helps to open the valve.

#26. Rocker arm:

The rocker arm of an internal combustion engine is an oscillating lever that changes radial movement into linear movement; this kind of device is properly known as a reciprocating lever.

With the help of the spinning motion of the overhead camshaft that opens and closes the valves and turns it into the up-and-down movement.

Rocker arms are generally made of steel. Rocker arms have contained high strength for their weight, and employ a good deal of leverage.

So both rocker arm and push rod are used in automotive vehicles in opening and closing of valves and to make transmission between crank end to the camshaft.

Depend upon the engine block or their up head block or down head, so it depends on which engine we are using. Rocker arm is used to thurst the springs to opening and closing of inlet and exhaust valves.

#27. Sensor:

Today in modern times vehicles are equipped with a various and wide range of sensors.

A sensor is an input device that helps to monitor almost everything, the sensor provides variable data information on an engine function.

Sensors perform various tasks simultaneously. It can identify the problems or issues before any breakdown and provide a countermeasure for that causes.

Sensors ensure that the vehicle will work very efficiently, smoothly, and safely.

Examples of sensors are crank angle sensor (CAS), airflow sensor (AFS), throttle potentiometer sensor (TPS), etc. These all provide various data on rpm, load, throttle opening, temperature, etc.

All These data are signaled to the ECM, which helps in analyzing and identifying the results and computes an output signal. where the output signal is used to actuate an output device.

Engine sensors contain electromechanical devices that help to monitor the variety of parameters of the engine.

An engine control unit (ECU) is a very important device that is used in today’s modern time vehicles it provides essential functions which govern the vehicles very efficiently and effectively.

#28. Water Pump:

The purpose of the water pump is to provide continuously circulate the engine coolant all over the cooling system. For the engine’s cooling system the water pump is taken as the heart.

The water pump is also called the coolant pump because The water pump is used to constantly circulate coolant throughout the engine and regulate the coolant flow rate of the cooling system.

Water pump jobs to distribute the heat in internal combustion engines. Without a water pump, excessive heat can be produced in the engine and it causes various harmful damage due to overheating.

So In simple ways pump’s job is to keep the temperature of the engine at low levels by dissipating the heat. It is necessary to have a water pump in every vehicle to operate the automobile efficiently.

The water pump has seven basic components: The basic components of the water pump are Housing, Impeller, Shaft, Bearing, Hub or pulley, Seal, Mounting, and Gasket.

There are three types of the water pump are:

- Electrical water pumps

- Mechanical water pumps

- Water circulating pumps

Comments