Metal casting processes

Metal casting processes

•

Casting is one of the oldest manufacturing process.

It is the first step in making most of the products.

• Steps:

-

Making mould cavity

-

Material is first liquefied by properly

heating it in a suitable

furnace.

-

Liquid is poured into a prepared

mould cavity

-

allowed to solidify

-

product is taken out of the mould cavity, trimmed and made to shape

We should

concentrate on the following for successful casting

operation:

(i)Preparation of moulds of patterns

(ii)Melting and pouring of

the liquefied metal

(iii)

cooling to room temperature (iv)Defects and inspection

Advantages

• Molten material can flow into very small sections

so that intricate shapes can be made by this process. As a

result, many other operations, such as machining, forging,

and welding, can be minimized.

•

Possible to cast practically any material: ferrous or non-ferrous.

•

The necessary tools required

for casting moulds are very simple and

inexpensive. As a result,

for production of a small lot, it is the ideal

process.

• There are certain

parts (like turbine blades) made

from metals and alloys that can only

be processed this way. Turbine blades:

Fully casting + last machining.

•

Size and weight of the product

is not a limitation for the casting process.

Limitations

•

Dimensional accuracy

and surface finish of

the castings made by sand casting processes

are a limitation to this technique.

•

Many new casting processes

have been developed

which can take into consideration the aspects of dimensional accuracy and surface

finish. Some of these processes

are die casting process, investment casting

process, vacuum-sealed moulding

process, and shell moulding process.

•

Metal casting is a labour intensive process

•

Automation: a question

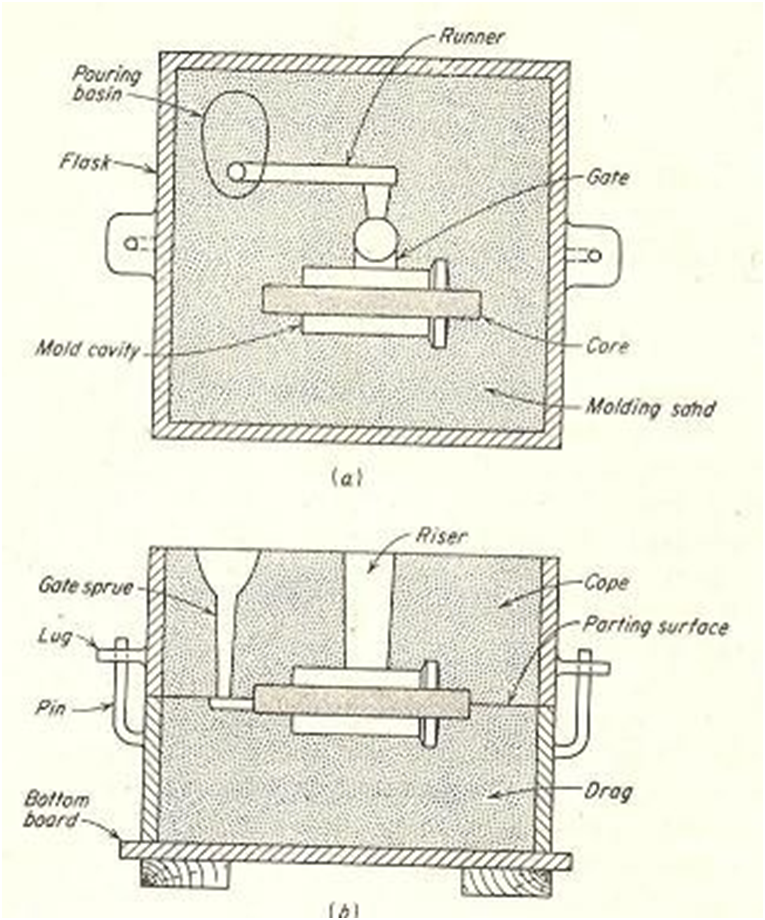

Typical sand mould

Important casting terms

Flask: A

metal or wood frame, without fixed top or bottom, in which

the mould is formed. Depending upon the

position of the flask in the moulding structure, it is referred to by various names such as drag – lower moulding flask, cope – upper moulding flask, cheek

– intermediate moulding

flask used in three piece moulding.

Pattern: It is the replica

of the final object to be made.

The mould cavity is made with the help of pattern.

Parting line: This is the dividing line between the two moulding

flasks that makes up the mould.

Moulding sand: Sand, which binds strongly

without losing its permeability to air or gases. It is a

mixture of silica sand, clay, and moisture

in appropriate proportions.

Facing sand: The small amount of carbonaceous material sprinkled on the inner surface

of the mould cavity to give a better surface finish to the castings.

Core: A separate part of the mould, made of sand and generally baked, which is used to create

openings and various shaped cavities in the castings.

Pouring basin: A small funnel

shaped cavity at the top of the mould into which the molten metal is poured.

Sprue: The passage through which the

molten metal, from the pouring basin, reaches the mould

cavity. In many cases it controls the flow of metal into the mould.

Runner: The channel

through which the molten metal is

carried from the sprue to the gate.

Gate:

A channel

through which the molten metal enters the mould cavity.

Chaplets: Chaplets are used to support the cores inside the mould cavity

to take care of its own weight and overcome

the metallostatic force.

Riser: A column of molten metal placed in the mould to feed the

castings as it shrinks and solidifies. Also known as “feed head”.

Vent: Small opening in the mould to facilitate escape of

air .

Comments