Computer Aided Inspection Using Robots

Computer Aided Inspection Using Robots

Integration of CAD/CAM with Inspection System

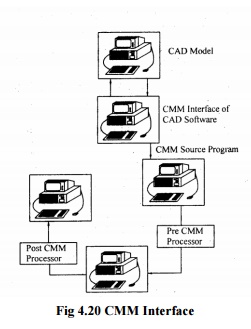

A product is designed, manufactured and inspected in one automatic process. One of the critical factors is in manufacturing equality assurance. The co-ordinate measuring machine assists in the equality assurance function. The productivity can be improved by interfacing with CAD/CAM system. This eliminates the labour, reduces preparation time and increases availability of CMM for inspection. Generally the CAD/CAM-CMM interface consists of a number of modules as given

(1) CMM interface

This interface allows to interact with the CAD/CAM database to generate a source file that can be converted to a CMM control data file. During source file creation, CMM probe path motions are simulated and displayed on the CAD/CAM workstation for visual verification. A set of CMM command allow the CMM interface to take advantage of most of the CMM functional capabilities. These command statement include set up, part datum control, feature construction, geometric relations, tolerance, output control and feature measurements like measurements of lines, points, arcs, circles, splines, conics, planes, analytic surfaces.

(2) Pre- processor

The pre-CMM processor converts the language source file generated by CMM interface into the language of the specified co ordinate measuring machine.

(3) Post-CMM processor

This creates wire frame surface model from the CMM-ASCII output file commands are inserted into the ASCJI-CMM output file to control the creation of CAD/CAM which include points, lines, arcs, circles, conics, splines and analytic surfaces.

Flexible Inspection System

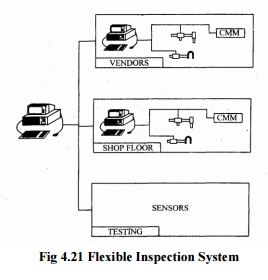

The block diagram of flexible inspection system is shown in figure. This system has been developed and the inspection done at several places in industry. This system helps product performance to improve inspection and increase productivity. FIS is the Real time processor to handle part dimensional data and as a multi programming system to perform manufacturing process control. The input devices used with this system are CMM’s;

Microprocessor based gauges and other inspection devices. The terminal provides interactive communication with personal computers where the programmes are stored. The data from CMMs and other terminals are fed into the main computer for analysis and feedback control. The equality control data and inspection data from each station are fed through the terminals to the main computer. The data will be communicated through telephone lines. Flexible inspection system involves more than one inspection station. The objective of the flexible inspection system is to have off time multi station automated dimensional verification system to increase the production rate and less inspection time and to maintain the inspection accuracy and data processing integrity.

Machine Vision

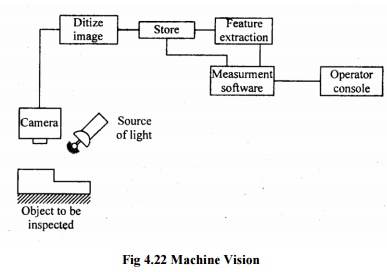

A Vision system can be defined as a system for automatic acquisition and analysis of images to obtain desired data for interpreting or controlling an activity. It is a technique which allows a sensor to view a scene and derive a numerical or logical decision without further human intervention. Machine vision can be defined as a means of simulating the image recognition and analysis capabilities of the human system with electronic and electro mechanical techniques. Machine vision system are now a days used to provide accurate and in expensive 100% inspection of work pieces. These are used for functions like gauging of dimensions, identification of shapes, measurement of distances, determining orientation of parts, quantifying motion-detecting surface shading etc. It is best suited for high production. These systems function without fatigue. This is suited for inspecting the masks used in the production of micro-electronic devices. Standoff distance up to one meter is possible.

Vision System

The schematic diagram of a typical vision system is shown. This system involves image acquisition; image processing Acquisition requires appropriate lighting. The camera and store digital image processing involves manipulating the digital image to simplify and reduce number of data points. Measurements can be carried out at any angle along the three reference axes x y and z without contacting the part. The measured values are then compared with the specified tolerance which stores in the memory of the computer.

Fig 4.22 Machine Vision

The main advantage of vision system is reduction of tooling and fixture costs, elimination of need for precise part location for handling robots and integrated automation of dimensional verification and defect detection.

Principle

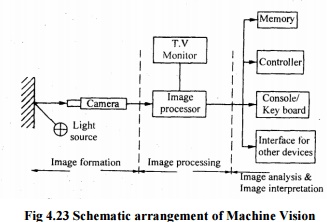

Four types of machine vision system and the schematic arrangement is shown

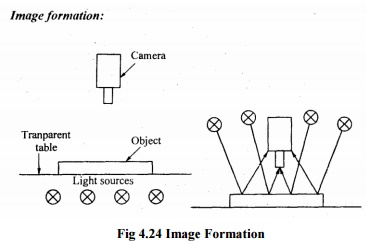

(i) Image formation.

(ii) Processing of image in a form suitable for analysis by computer.

(iii) Defining and analyzing the characteristic of image.

(iv)Interpretation of image and decision-making.

Fig 4.24 Image Formation

For formation of image suitable light source is required. It consists of incandescent light, fluorescent tube, fiber optic bundle, and arc lamp. Laser beam is used for triangulation system for measuring distance. Ultraviolet light is used to reduce glare or increase contrast. Proper illumination back lighting, front lighting, structured light is required. Back lighting is used to obtain maximum image contrast. The surface of the object is to be inspected by using front lighting. For inspecting three-dimensional feature structured lighting is required. An image sensor vidicon camera, CCD camera is used to generate the electronic signal representing the image. The image sensor collects light from the scene through a lens, using photosensitive target, converts into electronic signal.

Vidicon camera

Image is formed by focusing the incoming light through a series of lenses onto the photoconductive faceplate of the vidicon tube. The electron beam scans the photoconductive surface and produces an analog voltage proportional to the variation in light intensity for each scan line of the original scene.

Solid-state camera

The image sensors change coupled device (CCD) contain matrix of small array, photosensitive elements accurately spaced and fabricated on silicon chips using integrated circuit technology. Each detector converts in to analog signal corresponding to light intensity through the camera lens.

Image processor

A camera may form an image 30 times per sec at 33 m sec intervals. At each time interval the entire image frozen by an image processor for processing. An analog to digital converter is used to convert analog voltage of each detector in to digital value. If voltage level for each pixel is given by either 0 or I depending on threshold value. It is called binary system on the other hand grey scale system assigns upto 256 different values depending on intensity to each pixel. Grey scale system requires higher degree of image refinement, huge storage processing capability. For analysis 256 x 256 pixels image array up to 256 different pixel values will require 65000-8 bit storage locations at a speed of 30 images per second. Techniques windowing and image restoration are involved.

Windowing

Processing is the desired area of interest and ignores non-interested part of image.

Image restoration

Preparation of image during the pre-processing by removing the degrade. Blurring of lines, poor contrast between images and presence of noise are the degrading.

The quality may be improved

1) By improving the contrast by brightness addition.

2) By increasing the relative contrast between high and low intensity elements.

3) By Fourier domain processing.

4) Other techniques to reduce edge detection and run length encoding.

Image Analysis

Digital image of the object formed is analyzed in the central processing Unit of the system. Three important tasks performed by machine vision system are measuring the distance of an object from a vision system camera, determining object orientation and defining object position. The distance of an object from a vision system camera can be determined by triangulation technique. The object orientation can he determined by the methods of equivalent ellipse. The image can be interpreted by two-dimensional image. For complex three-dimensional objects boundary locations are determined and the image is segmented into distinct region.

Image Interpretation

This involves identification of on object. In binary system, the image is segmented on the basis of white and black pixels. The complex images can he interpreted by grey scale technique and algorithms. The most common image interpretation is template matching.

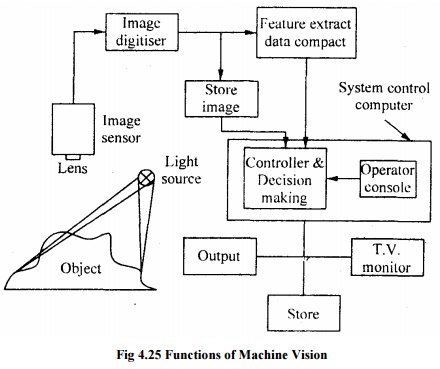

Function of Machine Vision

· Lighting and presentation of object to evaluated.

· It has great compact on repeatability, reliability and accuracy.

· I.ighting source and projection should be chosen and give sharp contrast.

· Images sensor compressor TV camera may he vidicon or solid state.

· For simple processing, analog comparator and a computer controller to convert the video information to a binary image is used.

· Data compactor employs a high speed away processor to provide high speed processing of the input image data.

· System control computer communicates with the operator and make decision about the part being inspected.

· The output and peripheral devices operate the control of the system. The output enables the vision system to either control a process or provide caution and orientation information two a robot, etc.

· These operate under the control of the system control of computer.

Fig 4.25 Functions of Machine Vision

Applications

· Machine vision can he used to replace human vision fur welding. Machining and maintained relationship between tool and work piece and assembly of parts to analyze the parts.

This is frequently used for printed circuit board inspection to ensure minimum conduction width and spacing between conductors. These are used for weld seam tracking, robot guideness and control, inspection of microelectronic devices and tooling, on line inspection in machining operation, assemblies monitoring high-

speed packaging equipment etc.

· It gives recognition of an object from its image. These are designed to have strong geometric feature interpretation capabilities and pa handling equipment.

Comments